As the main wearing part of the vibrating screen, the screen is directly in contact with the material during the production process. Once the material is selected improperly, it is easy to be damaged too quickly. At present, the material of the screen is mainly divided into two kinds: metal and non-metal. Metal materials include low-carbon, high-carbon, high-manganese steel, stainless steel, etc., and non-metal materials are mostly rubber, nylon, polyurethane, etc. In order to facilitate the correct selection, this article introduces the performance characteristics of several common mining screens.

High manganese steel screen

Among the many materials, the more reliable quality is the high manganese steel screen. It is a screen product woven by manganese steel mesh wire with a diameter of 1.6mm-12mm. It adopts an embedded weaving method. The warp and weft overlap points are not prominent. The screen surface is flat and the force is even. Plasticity and toughness can achieve better results, and service life is more guaranteed.

High manganese steel has high strength, rigidity, and bearing capacity. When subjected to strong impact and friction, the surface will produce strong work hardening due to plastic deformation, and the surface hardness can be increased to above HRC60, thereby obtaining high wear resistance, While the interior still maintains high plasticity and toughness.

In addition, when the old surface is worn out, the new surface will form a wear-resistant layer, so the service life can reach 4-8 times that of ordinary screens. It is mostly used in large-scale mining industries. It can also be used as a protective net for mechanical vibrating screens, Roller screen machine, electromagnetic high-frequency screen machine and asphalt mixing machine, etc.

Polyurethane screen

Polyurethane screens are also easier to use and have better wear resistance. Polyurethane itself has very high elastic modulus, high strength and impact absorption, high wear resistance, and high tensile strength, so its bearing capacity is relatively high. It is more than 2.5 times that of rubber sieve plates, and its service life is 8-10 times longer than that of ordinary metal sieve plates, 3 times that of stainless steel screens, and 3.9 times that of natural rubber. It is the current screen material with better wear resistance.

The production material of the polyurethane screen is a polymer organic elastomer, which has excellent abrasion resistance, flexibility resistance, and large bearing capacity, and has been specially treated to ensure that it will never delaminate under long-term alternating loads.

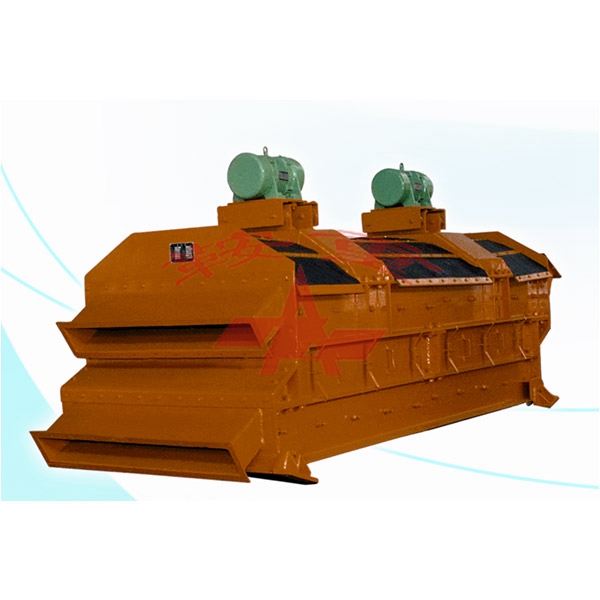

The above information is provided by medium vibrating screen manufacturer.

Previous: What Should be Done to Improve the Efficiency of Fluidized Bed Equipment?

Next: Mung Bean/Soybean Grain Cleaning Machine Production Plant

Copyright:@2020-2021

Comments Please sign in or sign up to post.

0

0 of 500 characters used