As a Food Extruder Machine Supplier, let's talk about the basic principles of extrusion technology. The core equipment for the continuous extrusion cooking process is the extruder. The extruder has the functions of compression, mixing, mixing, melting, puffing and molding. The cavity of the extruder can be divided into 3-5 zones, each zone can be heated by steam or electric, or can be heated by extrusion friction to achieve the purpose of cooking materials, the material is in the cavity under the action of high temperature and high pressure, starch Gelatinization, protein denaturation. When the material passes through the various regions of the extruder chamber, soluble flavor materials and pigments can be injected into the material through the cavity under the action of high pressure. At the end of the extrusion chamber, the molten material is extruded through the die hole of the template under the action of high pressure. Due to the sudden drop of pressure, the water vapor rapidly expands and dissipates, causing the product to form a porous structure, and then the expanded material is The rotary knife cuts into a certain size product. Single-screw extruders and twin-screw extruders are often used in breakfast cereal production, while twin-screw extruders are more advantageous than single-screw extruders because of the size and moisture of the single-screw extruder. The requirements and components are strict, and it is easy to produce problems such as backflow of materials and easy wear of the screw.

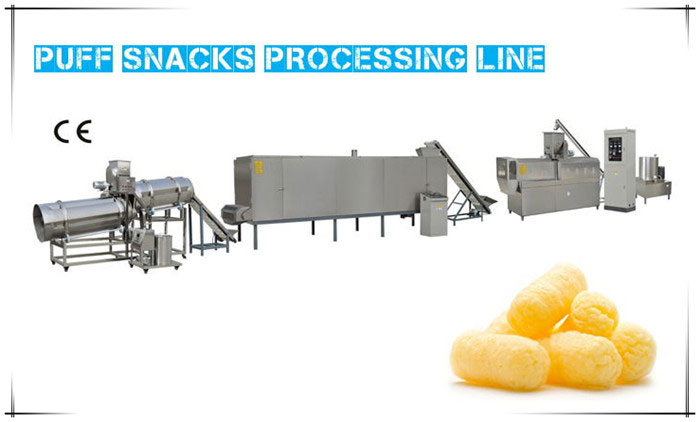

Our company offers Puff Snacks Extruder. If you are interested in our products, please contact us.

Previous: WELCOME TO EACO

Next: Pipe Pinching Rotator– YGHB Series adjustable welding rotator supplier

Copyright:@2020-2021

Comments Please sign in or sign up to post.

0

0 of 500 characters used