A few years ago, 3D printing technology sprung up, and it spread all over the Internet overnight and entered the field of vision of ordinary people. But in fact, as early as 1986, the United States produced the first industrial 3D Printer. In the following 20 years, researchers from various countries have continued to explore and develop 3D printing technology, which has led to the rapid development of 3D printing technology and the continuous expansion of application fields, industrial manufacturing, aerospace Aviation, automotive, architecture, design, medical, etc. have applications.

Now 3D printing has gradually entered homes and schools, becoming small appliances. So, what are the advantages of 3D printers?

Traditional manufacturing techniques and craftsmen have limited product shapes. Designers’ designs are often restricted by the tools they use. Many designs only exist in the mind and on paper and cannot be realized. But 3D printing technology can break through these limitations, open up a huge design space, and allow designers to create without restriction.

A 3D printer can produce many shapes and models, and he can make unused products every time like a craftsman. As small as screws, as large as house construction. For a family of three, children can print toy figures, and parents can print common furniture or office supplies.

3D printing can integrate the model. Through layered manufacturing, a door and its matching hinge can be printed at the same time without assembly. (If the printing is more delicate and complicated, it can also be separated and printed, but the assembly is convenient.) Omitting assembly shortens the supply chain and saves labor and transportation costs. The shorter the supply chain, the less pollution.

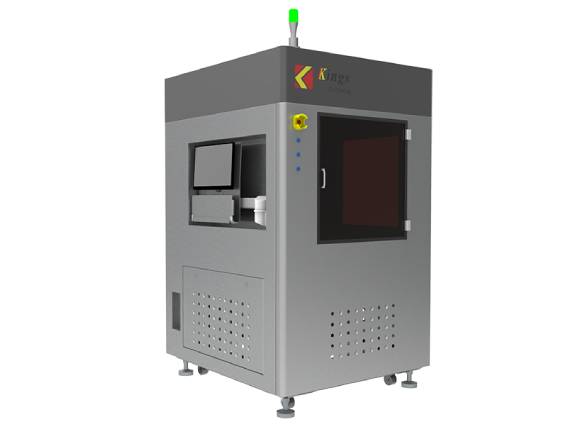

Rapid Prototyping 3D Printer

3D printers are industrial grade, desktop grade, ordinary home or office use, Laser 3D Printers can be selected, it is small and convenient, the required physical space is small, after debugging, the printing equipment can be moved freely, which is very convenient.

The 3D printer obtains various instructions from the design documents, and it requires much less operating skills than the injection molding machine to make the same complex items as the traditional manufacturing.

3D printers can print on demand. Even if production reduces the company's inventory, companies can also use 3D printers to create unique products to meet customer needs. So new business models become possible. If people produce nearby products on demand, zero-time delivery can minimize the cost of long-distance transportation.

3D printers can create their own products according to personal needs

The Rapid Prototyping 3D Printer can accurately and perfectly complete the physical copy, which is often used in the restoration of cultural relics and the data retention of cultural relics. The use of 3D scanners and 3D printing technology can realize the transformation between the physical world and the digital world and improve the resolution. We can scan, edit and copy physical objects, create exact copies or optimize originals.

Copyright:@2020-2021

Comments Please sign in or sign up to post.

0

0 of 500 characters used