Currently, there are three series of international container standards with a total of 15 types. Among the 15 types of containers, which specifications are appropriate should be determined according to the specific supply conditions and port conditions on the route and the transit route, because this has a major relationship with the successful completion of the resident container transportation.

Generally speaking, on the routes with less freight volume, the size of the container should not be too large. Of course, depending on the density of the goods, if there are many light dumps in the import and export goods, it is better to use a container with a larger size.

In addition, when deciding which container size to choose, the issue of cooperation with foreign shipping companies and cargo owners should also be considered. Because, in the international multimodal transport of container cargo, it is very likely to exchange and interoperate with foreign shipping companies.

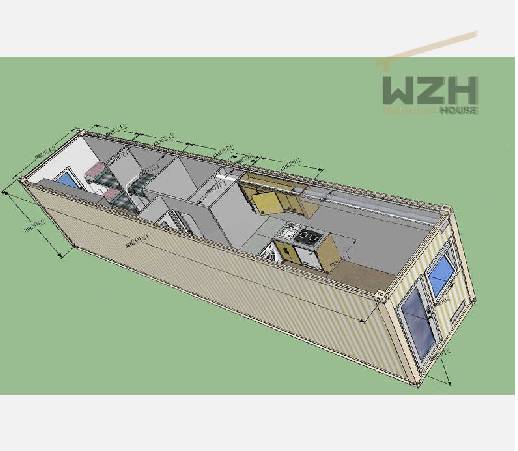

Standard Prefabricated Luxury container Home

Therefore, it is best to choose a container model widely used internationally. The international multimodal transport of containers should be based on the principle of "door-to-door" transport. Therefore, when choosing container transportation, we must pay attention to the conditions of inland transportation. In order to adapt to road and rail transportation conditions, countries and regions with low freight volume and poor transportation conditions can also realize "door-to-door" transportation, and the "child-mother box" transportation method can be adopted. The transportation method of the child-mother box means that the size of the child box should be closely matched with the size of the mother box. Large-scale international standard boxes can be used for sea transportation, and small container transportation is used for inland transportation. After the mature development of container transportation and the increase in freight volume, we will gradually improve the "door-to-door" transportation of large containers.

In addition, some routes often suffer from unbalanced cargo supply between the two ports, resulting in a large number of containers back to air transportation, which will not only reduce the economic benefits of container transportation, but also seriously affect the development of container transportation. In order to solve the problem of returning empty containers, shipping companies in some countries use collapsible containers (COLLAPSIBLE CONTAINER) on routes with unbalanced cargo sources. After the container is folded, its volume is only 1/4 of the fixed container, that is to say, after the four containers are folded, they overlap to form the volume of a fixed international standard container. This method can greatly reduce the loss of capacity when empty containers are returned.

When choosing a container, the main consideration is to use suitable boxes according to the different types, properties, shapes, packaging, volume, weight and transportation requirements of the goods. First of all, we must consider whether the goods can be loaded, and then we must consider whether it is economically reasonable and meets the transportation conditions required by the goods. The container must go through strict inspection before loading the goods. A defective container may cause damage to the cargo, or may cause a crash or death in the course of transportation and loading and unloading. Therefore, the inspection of containers is one of the basic conditions for the safe transportation of goods. When the consignor, carrier, consignee and other related parties hand over each other, in addition to inspecting the box, the state of the box at the time of handover should be confirmed in written form such as the equipment handover form. Generally, the inspection of containers should:

1. External inspection. External inspection refers to six-sided inspection of the box to see if there are any abnormal conditions such as damage, deformation, or breakage on the outside.

2. Internal inspection. The internal inspection is to inspect the inside of the box on six sides to see if there is water leakage, light leakage, stains, water marks, etc.

3. Check the door. Check whether the box door is intact, whether the door is watertight, whether the door lock is complete, and whether the box door can be opened repeatedly.

4. Cleaning inspection. The cleaning inspection refers to whether there are residues, contaminants, rusty odor and water in the box. If it does not meet the requirements, it should be cleaned or even replaced.

5. Inspection of attachments. The inspection of attachments refers to the reinforced ring connection status of the container, such as the inspection of the support of the pallet-type container, the extension structure of the flat container and the open container.

Previous: Bypass Double Slider Doors Glass Shower Enclosure

Next: Brass Wire Mesh

Copyright:@2020-2021

Comments Please sign in or sign up to post.

0

0 of 500 characters used