The US FDA said it inspected 67 KN95 masks produced by Chinese manufacturers. In the particle filtration efficiency test, 60% failed to reach the lowest 95% filtration standard. One of the manufacturers' N95 masks had a particle filtration efficiency as low as 24%.Then the question is coming. Can masks really shut out the new crown virus? In fact, the gap of the Meltblown Cloth produced is much larger than the size of the new coronavirus, but the virus cannot exist independently, we only need to intercept or block the attached virus droplets!

Melt blown cloth does not simply block the virus, but uses electrostatic adsorption to adsorb the virus on the melt blown cloth. The filtering performance of the meltblown cloth itself is about 35%, and the filtering performance can be increased to 95% after the electret treatment has an electrostatic effect. At this time, the main body of the Meltblown Machine plays a key role!

The spinneret used in the melt-blown method is different from other spinning methods in that the spinneret holes must be arranged in a straight line, and the upper and lower sides have high-speed air jet slots. The hole diameter of the melt blown spinneret is 0.15-0.4mm, and the pitch of the spinneret is 0.7mm. Let the delicacy fill all the products.

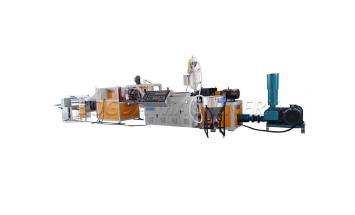

Meltblown Machine

The filter screen of the Meltblown Filter Nonwoven Fabric Machine is a woven wire mesh disk or a stainless steel mesh disk. Usually several layers of different meshes form a group. The outer coarse mesh is firmer and prevents larger particles from entering the inner fine mesh prematurely. The finer inner mesh can filter the smaller solid particles in the melt stream. If the pressure reaches the set value, the extrusion volume is significantly reduced, and the power consumption of the screw extruder increases, the filter should be replaced in time.

The function is to accurately measure, continuously convey the melt-blown PP material melt to the melt-blown die, and generate a predetermined pressure to ensure that the melt can overcome the resistance of the components and the spinneret to be ejected from the spinneret to form a trickle of melt .

Previous: Several Common Faults and Solutions of Bag Making Machines

Next: Annular Conveyor Belt jointless annular conveyor belt rubber belting conveyor belt manufacturers

Copyright:@2020-2021

Comments Please sign in or sign up to post.

0

0 of 500 characters used