PVC Shrink Film is widely used in the outer packaging of various products such as beer, beverages, building materials, food, medicine, sterilized tableware, cultural and sports goods, craft gifts, printed matter, etc. Especially in the combined packaging of irregularly shaped items or commodities On the one hand, it can not only meet the functions of moisture-proof, dust-proof, touch-proof, transparent display, etc. but also increase the attractiveness of the product. It can also be used to replace all kinds of cartons, which not only saves packaging costs but also conforms to packaging trends. Can be processed into flat bags, arc-shaped bags, tube bags, etc.

Packaging film has puncture resistance, super strength and high performance, so it is widely used, but many customers report that the surface of the packaging film will appear spots during the use of the packaging film. Let's follow the packaging film manufacturers to understand why they appear. The cause of the spots.

If the viscosity of the adhesive of the packaging film is too large, the fluidity will be poor, which will easily cause uneven gluing, affect the reflective performance of the aluminum coating surface, and cause spots. The surface tension of the packaging film ink is low, resulting in poor coating effect of the adhesive and uneven gluing. Therefore, the adhesion between the ink layer and the aluminized layer and the tightness between the layers will vary, resulting in aluminized The reflective effect on the surface of the layer is also strong or weak, visually forming white or gray spots. Packaging film manufacturers remind everyone that if the hiding power of the ink is not strong or the leveling is poor, it will cause uneven coverage. Where the covering effect is not good, the color of the aluminized layer will penetrate through the ink. The concentration of the adhesive is too high, the viscosity is too large, it is easy to reverse the ink to the glue, and change the color of the printed layer.

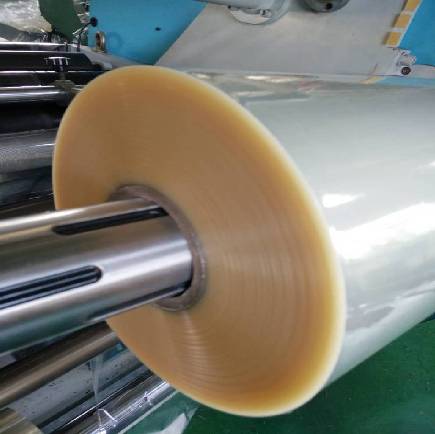

PVC Shrink Film

The PVC Heat Shrink Film is made of ethylene PVC resin mixed with more than a dozen auxiliary materials and then inflated twice. It has the characteristics of good transparency, high strength, easy shrinkage, and the shrinkage rate can be adjusted freely according to user needs, and it has strong operability.

Product features: PVC Heat Shrinkable Film is made of ethylene PVC resin mixed with more than ten kinds of auxiliary materials and then inflated twice. It has good transparency, high strength, easy shrinkage, and shrinkage rate can be adjusted freely according to user needs, and it is operability Strong.

Product categories: The products are divided into general grade, medical-grade, and high-strength grade. They can be made into a tubular film, L-shaped half-folded film and monolithic film, and can be processed into tube bags, flat bags, trapezoidal bags, circular arc bags, etc.

Application range: widely used in food, wine, sports goods, daily necessities, sterilized tableware, electronic appliances, handicrafts, maintenance products, audio-visual products, portals, medicines, stationery, toys, plastic hardware, glass ceramics, etc. package.

Copyright:@2020-2021

Comments Please sign in or sign up to post.

0

0 of 500 characters used