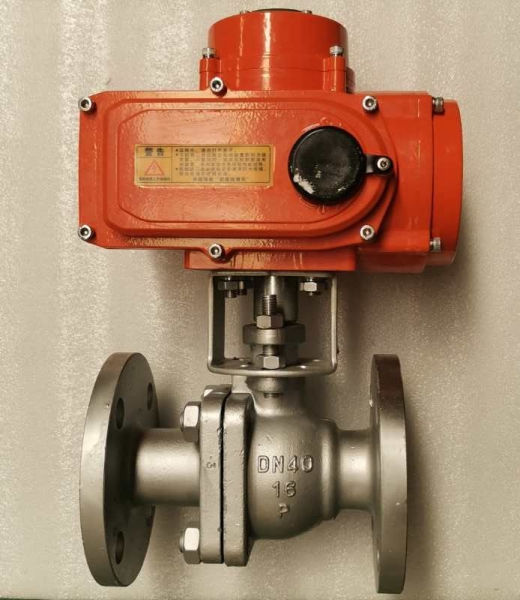

If dirt enters the compressor, it will cause the cylinder to be rough and the valve plate is not tightly sealed, which will affect the normal operation of the compressor. If dirt enters the throttle valve, it will cause dirt and blockage. Although every equipment and pipeline has been de-rusted and blown before installation, during the installation of the entire system, many pipes will still have some welding slag, iron filings, and dust falling from the welding port into the pipe during welding. The sewage of the whole system can be further removed. Our company provides freon valve.

Blowdown of the refrigeration system

1. The equipment pipes of the refrigeration system must be drained before the operation to remove the welding slag, iron filings, sand, and other dirt remaining in the system during the installation process. Prevent dirt from damaging the components of the refrigerator and the valves in the system, and avoid blockage of the system pipeline.

2. When the ammonia refrigeration system discharges sewage, an air compressor or an ammonia refrigerator can be used to provide compressed air, and the pressure of the compressed air generally does not exceed 0.6 MPa. The sewage outlet should be set at the lowest point of the pipeline, and the sewage work can be grouped and carried out in layers.

3. Sewage discharge is generally no less than 3 times until the discharged gas is free of water vapor, oil, rust, and other debris.

4. In order to effectively utilize the explosive force and high-speed airflow of the compressed gas, it is recommended to install a valve on the sewage outlet, and quickly open the valve when the pressure in the system rises, so that the gas can be discharged quickly and the dirt will be brought out.

5. In practice, a wooden plug can also be used to block the sewage outlet. When the system has a certain pressure, the wooden plug is pulled out to quickly exhaust the air. This method is very good. But there is a certain danger, so be careful and pay attention to safety during operation.

6. The blowdown of the Freon system is also carried out after the installation of the system, using 0.6MPa nitrogen for segmental blowdown. The blowdown method and inspection are the same as the ammonia system. Compressed air cannot be used during the blowdown and pressure test of the Freon system. The compressed air contains water vapor. If it remains in the Freon system, it will cause ice blockage or ice blockage in the Freon system.

7. In the process of sewage discharge, if there is obvious leakage of the pipeline flange valve, it should be remedied in time. After the system is drained, the spools and filters of all valves in the system should be disassembled and cleaned.

The above information is provided by the refrigeration valve supplier.

Copyright:@2020-2021

Comments Please sign in or sign up to post.

0

0 of 500 characters used