Among the components of the entire cabinet, the door panel is equivalent to the face of the cabinet, and different styles and textures can be formed by changing the style, line type, color, material, and processing method of the cabinet door. The natural texture and texture of solid wood cabinet doors and their changeable shapes have always been loved by consumers. Therefore, the high frequency joining machine manufacturer will introduce the superiority of high-frequency machines in the assembly of solid wood cabinet doors.

First, we must understand the structure of solid wood cabinet doors. The production process of door panels of different structures is different. The solid wood door panel is usually a frame structure, combined in a four-in-one manner, that is, four frames plus a core board. This structure is strong and beautiful, but it is not so simple to produce.

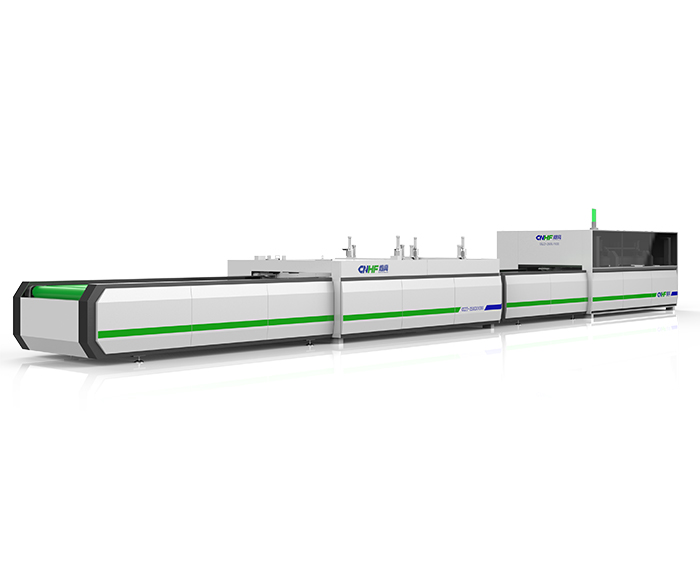

In order to meet the high-precision, fast, and high-quality framing requirements, a high-frequency frame assembly machine is a good choice. It is said that these are the three key reasons for making doors efficiently and conveniently:

First of all, effective framing is the key to improving efficiency. The high-frequency frame assembly machine can cure the glue in only 2-20 seconds, which can be streamlined;

Secondly, the accurate frame assembly is the guarantee of quality. The high-frequency frame assembly machine does not require gun nails and has high adhesive strength. The equipment adopts imported ball screws and precise linear guides, and is precisely controlled by a motor, with high precision after assembly;

Third, convenient assembly is the liberation of manpower and material resources. The High-frequency frame joining machine does not require manual assembly and proofreading, saving time and energy, convenient man-machine interface, and parameter adjustment of assembly pressure, current, time, etc.

Adjustment after assembly

After assembly, the door panel needs to be sanded again with a sander with a fixed thickness. Then, through heavy-duty double-end milling, heavy-duty double-end milling is used for square milling and size control of solid wood door panels to ensure that the dimensional accuracy of the door panels is controlled within plus or minus 0.2mm.

Then pass the ground solid wood door panel through a sanding machine to polish the four sides of the door panel to achieve the condition of polishing paint. After inspection, the door panel will be trimmed and repaired to make the oblique line consistent, then sanded with 240# sandpaper, and then the hinge hole will be made.

At this time, place the door panel in the dehumidification room to maintain health, and control the moisture content of the wood within the corresponding standard according to the average annual moisture content of the area and the air.

After the assembly and adjustment, the processing of the solid wood cabinet doors has been basically completed. After inspection and packaging, it can be shipped out.

Copyright:@2020-2021

Comments Please sign in or sign up to post.

0

0 of 500 characters used